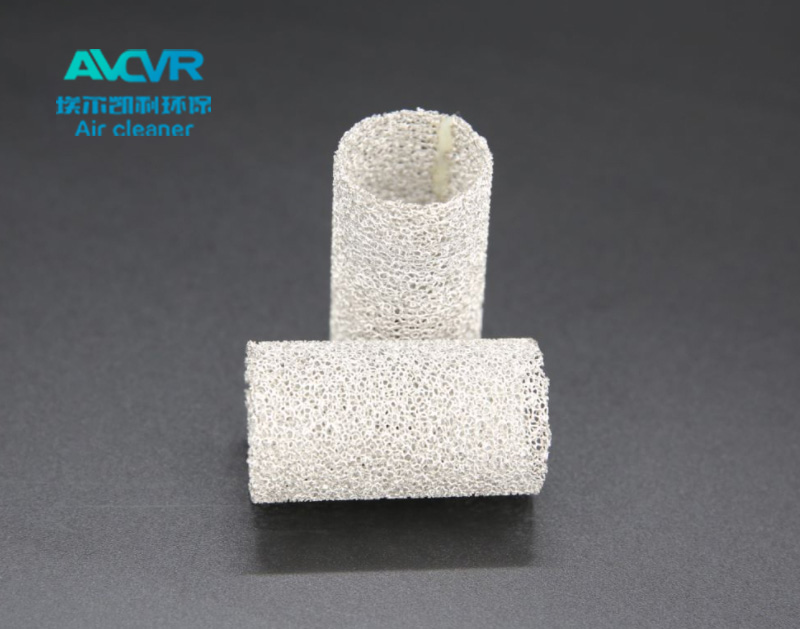

AOP Sterilization, Sterilization Filter Foamed Metal Substrate optional carrier: Nickel-iron alloy, pure nickel, copper Features: high temperature resistance, high decomposition efficiency, long life, full coating, custom size, custom frame

全国服务热线: 188-6236-8393

在线咨询AOP is the abbreviation of Advanced Oxidation Processes, which was proposed by Glaze et al. (1987). AOP overcomes the disadvantages of ordinary Oxidation methods, such as weak Oxidation ability and selective Oxidation.The most distinguishing feature of AOP is main oxidant hydroxyl radicals react with organic matter, generated in the reaction of grapefruit free radicals can continue to take part in the hydroxyl free radical chain reaction, or through organic peroxide radicals generated after oxidizing decomposition reaction until further degradation for the final product of CO2 and H2O, so as to achieve the goal of the oxidative decomposition of organic matter.

Air clean environmental protection AOP sterilization, sterilization products are based on AOP theory to enhance the product formula, through the modular design and reaction medium special coating process to form modular products and filter supplies for different application fields.

AOP sterilization products mainly use: polyurethane sponge, foam metal as the carrier.

Main product shape: cylinder shape.

optional carrier: Nickel-iron alloy, pure nickel, copper

Features: high temperature resistance, high decomposition efficiency, long life, full coating, custom size, custom frame

淘宝

淘宝